Blog Rabatec

Innovations in Lead Recycling: Meeting the Dual Challenge of Yield and Environmental Compliance

Lead recycling, primarily focused on recovering lead from spent lead-acid batteries (SLABs), faces the constant dual challenge of maximizing metallic yield while adhering to increasingly stringent environmental compliance standards. Modern innovations are concentrating on process efficiency and material science to meet these demands, particularly in smelting and emissions control.

Phase 1: Maximizing Yield Through Furnace Innovation

The core of lead recycling involves smelting the lead-bearing components (paste and grids) to produce molten lead and slag. Innovations here focus on improving thermal efficiency and optimizing the chemistry for metal separation.

1. Enhanced Smelting Technologies

Traditional reverberatory furnaces are being replaced or supplemented by more efficient systems:

- Rotary Tilting Furnaces (RTF): These are versatile and offer superior control over the smelting atmosphere. By continuously rotating the charge, they maximize contact between the materials and flux, promoting faster reactions and more efficient reduction of lead compounds in the paste. This leads to higher metallic yield and lower fuel consumption (a process optimization gain).

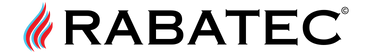

- Controlling PbO in Slag: The primary yield loss occurs when lead oxide (PbO) remains trapped in the final discard slag. Modern smelting strategies involve precise control over the fluxing agents (raw materials – slag & fluxing agents) and temperature to ensure PbO is reduced back to metallic lead (Pb), minimizing losses to the slag phase.

2. Specialized Flow Control

After smelting, handling the molten lead is critical to prevent re-oxidation and ensure high purity.

- Inert Gas Blanketing: Utilizing advanced flow control and specialized systems to inject or blanket the molten lead in holding kettles with inert gas (like nitrogen). This minimizes contact with oxygen, preventing the formation of dross (lead oxides), thereby increasing final yield and reducing the need for repeated refining.

Phase 2: Meeting Environmental Compliance (Emissions Control)

Lead is highly toxic, making stringent control of gaseous and particulate emissions non-negotiable. Modern innovations focus on capturing ultra-fine lead-bearing dusts and sulfur dioxide (SO₂).

1. Advanced Baghouse Filtration

- High-Efficiency Particulate Air (HEPA) Filters: While standard baghouses capture the majority of coarse dust, modern systems are incorporating HEPA filters and specialized filter media designed to capture the ultra-fine lead oxide and sulfate particles that pose the greatest health risk.

- Temperature and Chemical Conditioning: Before filtration, the off-gases are chemically conditioned (often by injecting lime or soda ash) and cooled. This process stabilizes the lead compounds and prevents “blinding” (clogging) of the filter bags, improving the efficiency of the equipment and ensuring long-term emissions compliance.

2. SO₂ Control and Scrubbing

SLABs contain sulfates, which release SO₂—a major pollutant—during smelting.

- Wet Scrubbers and Dry Sorbents: Modern plants integrate multi-stage scrubbing systems. Wet scrubbers use chemical solutions to absorb SO₂, while dry sorbent injection systems introduce alkaline powders into the gas stream. Both methods chemically neutralize the SO₂, converting it into a stable, non-toxic salt that can be safely collected and managed, meeting strict air quality standards.

3. Comprehensive Handling & Safety

Beyond process control, facilities rely on strict protocols and equipment to protect personnel.

- Enclosed Systems and Negative Pressure: All material handling areas (charging, tapping, dross removal) operate under negative pressure, ensuring air flows into the system and preventing lead dust from escaping into the workplace, supporting handling & safety protocols.

- Continuous Monitoring: State-of-the-art measurement and control systems are used for continuous ambient air monitoring and stack emissions testing, often feeding into the plant’s emergency shutdown system (ESD) if limits are exceeded.

By adopting these innovations, the lead recycling industry is successfully optimizing yield through superior metallurgy and ensuring critical long-term environmental and occupational health compliance.