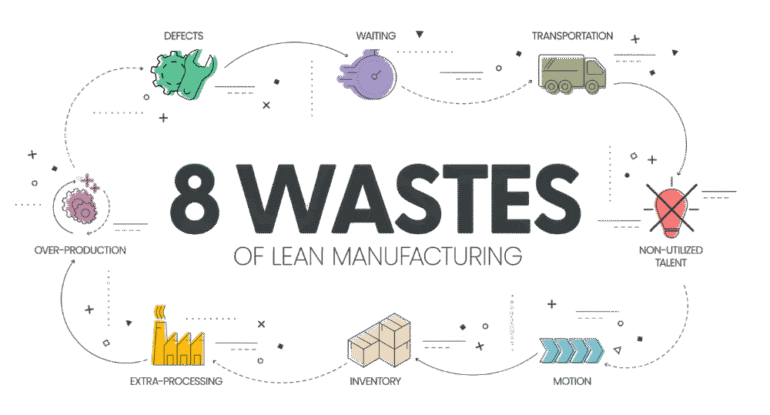

In every business process, from manufacturing a product to fulfilling a customer request, there is a hidden river of waste. This waste—which includes unnecessary waiting, overproduction, defects, and excess inventory—drains your company’s resources and slows down your ability to deliver value to your customers. Your team may be working hard, but if your process is filled with these inefficiencies, you are missing a massive opportunity to improve. The problem is that these non-value-added activities are often invisible unless you have a systematic way to see them.

Our Value Stream Analysis & Optimization consulting service provides that visibility. It’s a hands-on engagement where we work with your team to meticulously map out your entire value stream, from the moment a customer makes a request to the final delivery of the product or service. This visual representation reveals exactly where the waste is occurring, highlighting bottlenecks and inefficiencies. We then work with your team to design a future state that eliminates these issues. The result is a dramatic reduction in lead times, a significant decrease in operational costs, and the ability to deliver more value to your customers, faster than ever before.

Ready to turn these insights into action? A strategic Lean Six Sigma partner can help you move from analysis to implementation, ensuring your processes, projects, and people deliver maximum value. We provide the expertise and hands-on support to solve your toughest challenges and secure your capital investments. Contact us today to schedule a consultation and begin your journey toward operational excellence.